The Importance of Safety Glasses and Goggles

Do you work in an industry where you require safety goggles or glasses? Do you know if your current eyewear is industry compliant? Read on for information on how wearing proper safety glasses or protective goggles can keep your eyes safe for a lifetime of good vision.

Statistics

- Every day an estimated 1,000 eye injuries occur in the North American workplace.

- With proper eyewear, it is estimated that 90 per cent of these injuries could be prevented.

- Wearing the wrong kind of eye protection can be just as hazardous as not wearing any protection at all.

- Approximately 5 per cent of eye injuries will be debilitating enough to interfere with work on a short or long-term basis.

- Three out of five workers suffering eye injuries wore no eye protection. Half of those who did use safety eyewear wore the wrong type. To be effective, eye protection must be properly selected for the job and fitted to the wearer.

How Do I Know if my Eyewear is Safe?

In Canada the CSA (Canadian Standards Association) and in the USA the ANSI (American National Standards Instutite) oversees safety practices in the workplace and in educational settings. They determine standards which apply to eye safety. Look for the appropriate symbol on your eyewear to ensure that it is an approved product.

This includes several types of eye protection devices, including eyeglasses (both prescription and non-prescription), goggles, face shields, welding helmets and full-face respirators.

Jobs that pose a high risk for eye injury include those that involve:

- Chemicals

- Dusty environments

- Excessively bright lights or UV lights

- Compressed air

- Machines or tools that chip, chisel, cut, drill, grind, hammer, sand, smelt, spray or weld.

Common risk factors

Factors in the workplace that increase the risk of eye injury may include:

- The employer doesn’t supply any eye protection.

- The employer supplies eye protection but workers won’t wear it.

- The employer doesn’t enforce the use of eye protection or train the workers in how to use protection equipment.

- Neither the employer nor the workers appreciate the potential for injury and don’t think to use eye protection.

- The eye protection is inadequate, such as the use of glasses when the job requires a face shield.

- The eye protection doesn’t fit properly – for example, the glasses are loose and allow particles to enter from the sides.

- Only the operator of the machine wears eye protection, so anyone in the vicinity who is not wearing eye protection is at risk from flying particles.

- The workers don’t know how to properly operate the equipment or tools.

- The equipment isn’t maintained in good repair.

- Work involves the use of metal on metal, such as hammer and chisel injuries.

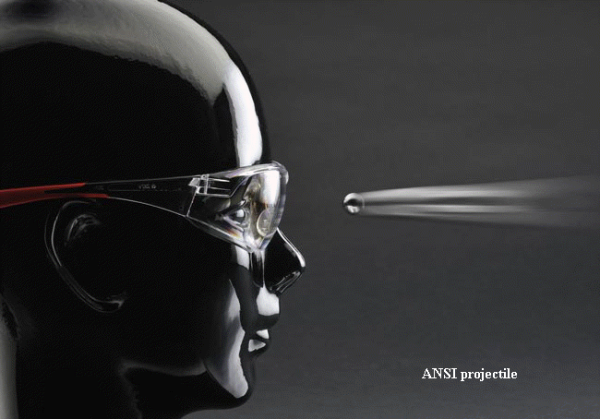

Eyewear Testing

- For the basic impact tests, lenses are tested separately (not mounted in a frame). For the high impact classification, the frame and lenses are tested together as a unit.

- Safety lenses now have two classifications of performance: basic impact and high impact.

- The “drop ball” test determines the basic impact safety classification for lenses. In this test, a one-inch diameter steel ball is dropped onto the lens from a height of 50 inches. To pass, the lens must not crack, chip or break. All glass safety lenses must undergo this test. For plastic safety lenses, however, only a statistical sample of a large batch of lenses needs to be tested.

- In high impact testing, a high velocity test is performed by shooting a quarter-inch diameter steel ball at the lens at a speed of 150 feet per second. To pass, the lens must not crack; chip or break, and it must not become dislodged from the lens holder.

How to Choose and Use Safety Eyewear

- Match your eye protection to the hazard: goggles that protect you from dust may not protect you from splashes or radiation.

- Make sure the equipment fits properly. It should be snug but not uncomfortable.

- Always wear protective eyewear that was specifically designed for the task at hand.

- Keep your safety glasses on even when you wear other protection like a welding helmet or face shield. Flying chips or dust can get under the shield if you lift the visor.

- Never tamper with your equipment.

- Inspect plastic visors or protectors for scratches that may limit vision or cracks that can weaken the structural strength.

- Choose eye protection with polycarbonate lenses. Polycarbonate is impact and scratch resistant. Polycarbonate lenses are better at transmitting light and providing clear vision, and they are the thinnest and lightest lenses available.

- Always keep a spare pair of protective eyewear handy, just in case.

- Workers should wear safety eyewear whenever there is a chance of eye injury. In addition, anyone visiting or passing through areas that pose eye hazards should wear protective eyewear.

- Contact lens wearers must be especially careful and should always wear protective eyewear on site: dust and other particles can become lodged under the lens and can cause irritations or infections.

Use diligence when working in potentially hazardous situations. Always protect your eyes. They are your windows to the world.

Where do you go when you need special, unique and creative promotional items? The team at Level 2 Sportswear is waiting for you. We will work with you to source the perfect promotional product, trade show giveaway, corporate gift, or to develop a safety and service award program that your employees are sure to love.

OUR GOAL IS TO MAKE YOU LOOK GOOD!